The transportation of raw materials for glass production requires extreme wear-resistance of machines. Whether used for sharp-edged glass pieces or fine silica sand: When coated with Hawiflex® polyurethane glass pieces carts, hoppers and conveyors can withstand erosive material influences many times longer, thus reducing downtime and production costs – to your advantage. As Hawiflex® polyurethane prevents metallic abrasion, there is hardly any residue in the end product glass. At the same time, the noise level is reduced by up to 50 %.

Mixing blade

- Special formulation resistant against high temperatures

- Used in mixing process with raw materials for the glass production

Shard card

- Excellent cutting resistance

- Ideal for applications in the glass recycling industry

Hopper lining

- Single-part cone

- Simple installation

- No infiltration

- Easy to fix

- Excellent gliding properties

- Extremly long service life

Impact plate

- Standard plate

Transfer point for broken glass

- Spray coated

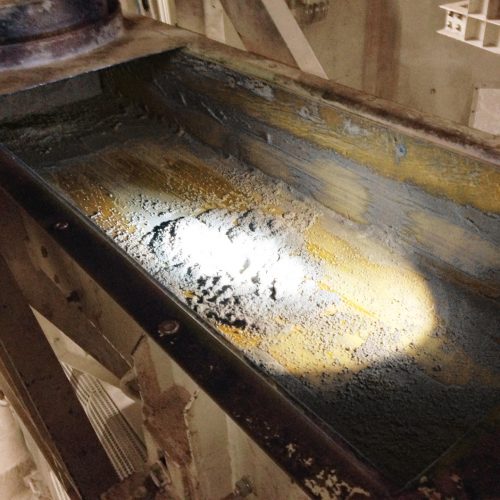

Vibrating chute

- Reduced adhesion

- Extended service life