Irrespective of what material you handle, process, mine or pour – Hawiflex® polyurethane offers you the advantage of protecting your valuable resources against wear, considerably extending service life, and significantly reducing downtimes and thus increasing availability.

Hawiflex® polyurethane has been successfully used in

- Crushed rock, sand and gravel works

- Coal and steel works

- Mining

- Cement works

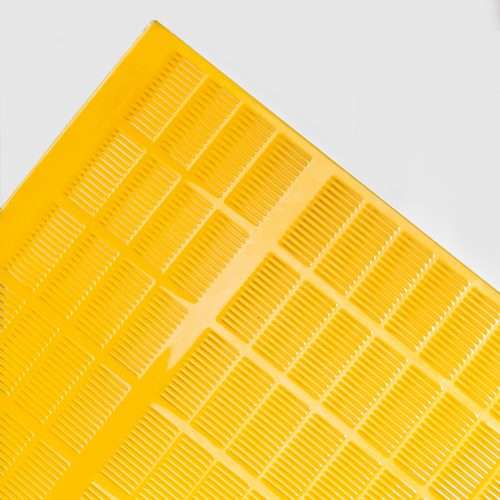

Slotted-hole screen mat

- Produced acc. to drawing or customer specification

- Permanent elastic

- Wear resistant

- Non-stick surface

Concrete spraying nozzle

Dead box

Conveyor scraper

- Easily clears bulk material from conveyor

- Very high-duty under extreme conditions

- Available with different Shore hardnesses

- For application in: Mining, gravel works, quarries

Rotor of a cellular wheel sluice

- Wear-resistant

- Easy to clean

Pipe bends

- Innovative wear protection

- Long service life and reliable

- Hawiflex® counteracts impact wear arising in pipe bends

Screw conveyor

- Produced acc. to drawing or customer specification

- Permanent elastic

- Wear resistant

- Non-stick surface

Hydrocyclone

- Specially adapted Hawiflex® polyurethane systems

- Optimum classification due to minimum inflation and excellent wear resistance

- UV and ozone resistant

- Physical properties remain during entire service life

- Resistant to hydrolysis

Discharge valve

- With rotating paddle sensor for sand classifiers

- Special formulation for sand and gravel industry

- High wear and pressure resistance