We are always fascinated to find out for which mechanical resilience engineering applications Hawiflex® polyurethane is used – from ultra large to minute applications. The emphasis is always on preventing wear and thus producing considerable potential savings. But sometimes it is also a question of offering resistance against aggressive chemical substances or high temperatures. No problem for Hawiflex® polyurethane, which meets all of these requirements.

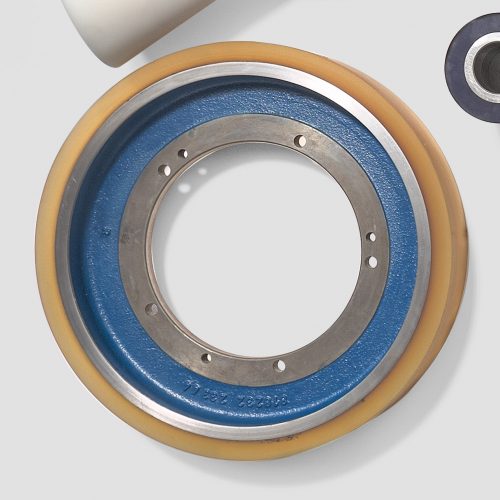

Wheel and roller coatings

- For exceptional requirements in coal mining, steel and aluminium industry

- Ability to absorb high loads with significantly longer service life compared to rubber-coated rollers

Capacities:

- Up to 2.500 mm diameters

- Up to 3.500 mm length

- Up to 10.000 kg weight of individual pieces

Wheels and rollers

- Special Hawiflex® polyurethane systems for applications requiring high loading capacity, speed and impact We are always fascinated to find out for which mechanical resilience.

Sealing element

- Excellent pressure deformation resistance

- Resistant against hydrolysis

Coupling collar

- Exact reproduction of complex shapes in couplings requiring high levels of precision

- Also suitable for high torque transmission application example:

- Very smooth running dialysis machine

Seals

- Resistant against numerous media to be sealed

Machine elements

- A variety of components and assemblies for mechanical engineering