Our impact protector is used as a complement or sole wear protection at transfer stations of conveyor belts, hoppers in sand and gravel industry and in the concrete industry for the supply of material sizes up to approx. 30mm. The impact protector is a urethane mold cast item that has two studs on the back which are welded to the inner perforated steel plate.

The catching pockets are arranged symmetrically and catch bulk material at a width of 275mm and a height of 650mm, which protects the impact protector from wear. Due to the slim design, assembly can be carried out easily with a unit weight of approx. 7 kg. Impact protectors can be mounted next to each other, which makes them suitable also for the lining of larger areas.

For applications with changing gravel sizes, we recommend our step plate, as this promotes your batch purity.

Tip: When using the impact protector for larger areas, partially worn areas can be replaced individually.

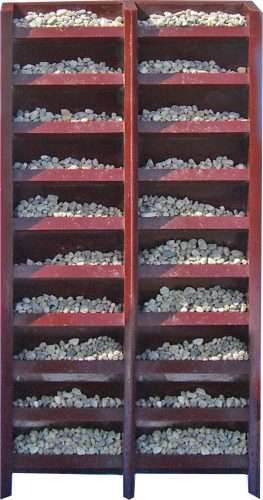

Impact protector als wear protection on a conveyor belt

Hawiflex® polyurethane benefits:

- Suitable for grain sizes up to 32 mm

- No shattering of coarse gravel upon impact

- Impact-proof and cut resistant

- Noise reducing

- Easy assembly thanks to studs at the rear

- Can be retrofitted in existing plants

- Lower maintenance expense due to long service life

Dimensions

Standard dimensions:

650 x 275 x 60 mm

Low dead weight:

Just approx. 7.2 kg